Popular Science | Non-Metallic Heating Material – Silicon Carbide (SiC) Rods

With the rapid development of industries such as aerospace, electronics, metallurgy, chemical engineering, transportation, automotive, and defense, the requirements for thermal processing and heat treatment of materials have become increasingly stringent. Electric heating has gained widespread popularity due to its advantages, including ease of control and adjustment, environmental friendliness, and the ability to improve product quality.

Common electric heating materials can be divided into two categories: metallic and non-metallic. Among them, non-metallic heating materials, such as silicon carbide (SiC), molybdenum disilicide, zirconia composites, and carbon-based materials, are gradually replacing metallic heating materials due to their high-temperature resistance, corrosion resistance, oxidation resistance, and high electrothermal conversion efficiency.

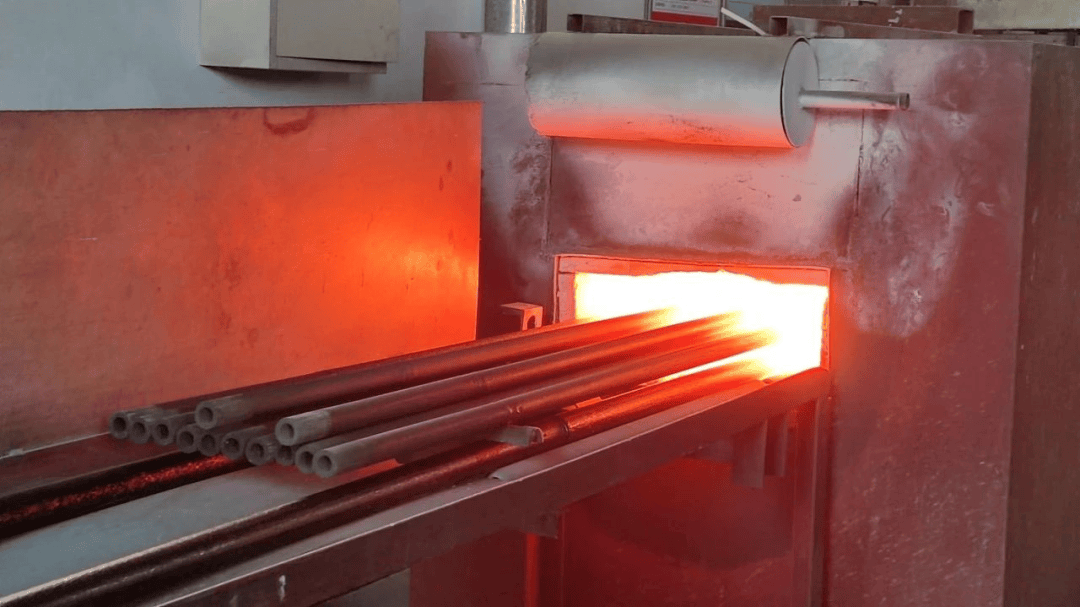

Silicon Carbide Heating Elements

SiC heating elements, commonly known as silicon carbide rods, are non-metallic heating elements made from high-purity green SiC as the primary raw material and crystallized at 2200°C. Their resistance varies with operating temperature and time. They exhibit a series of physical and chemical properties of silicon carbide products, demonstrating superior performance as inorganic high-temperature structural materials.

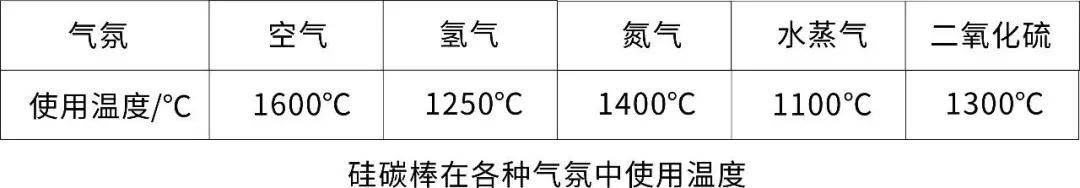

Ordinary SiC heating elements can operate at temperatures around 1400°C. However, through advanced technologies such as high-temperature sintering, ceramic surface coating, special additives, and immersion treatment of cold ends in molten silicon, specially designed SiC heating elements can operate at temperatures ranging from 1600°C to 1650°C, and even up to 1800°C in an argon atmosphere. Their normal continuous service life generally exceeds 2000 hours, and they can be directly powered by commercial electricity.

Advantages of Silicon Carbide Rods

The main advantages of silicon carbide rods include strong thermal radiation capability and precise temperature control. In industrial applications, they are often processed into rod, strip, plate, or U-shaped forms. They are easy to use, allowing for parallel, series, or mixed connections, and can be installed horizontally or vertically.

With a relatively high cost-performance ratio, silicon carbide rods are the most commonly used heating elements in medium- and high-temperature industrial and laboratory furnaces. They are widely applied in high-temperature industrial fields such as ceramics, glass, and refractory materials.

-------

Source and Disclaimer

The content of this article is compiled from online sources, and the copyright belongs to the original authors. This platform is for sharing and informational purposes only. If there are any concerns regarding infringement, please contact us for removal.