Currently, Southeast Asian nations are actively engaging in the Industry 4.0 wave centered on automation, intelligence, and sustainability. Within this profound industrial transformation, electric heating technology has transcended its conventional auxiliary role to emerge as an indispensable core engine driving manufacturing advancement. With its distinctive advantages of precision, efficiency, and environmental cleanliness, it injects critical momentum into the grand blueprint of Southeast Asia's Industry 4.0 revolution.

01

The "Thermal Foundation" of Precision Manufacturing

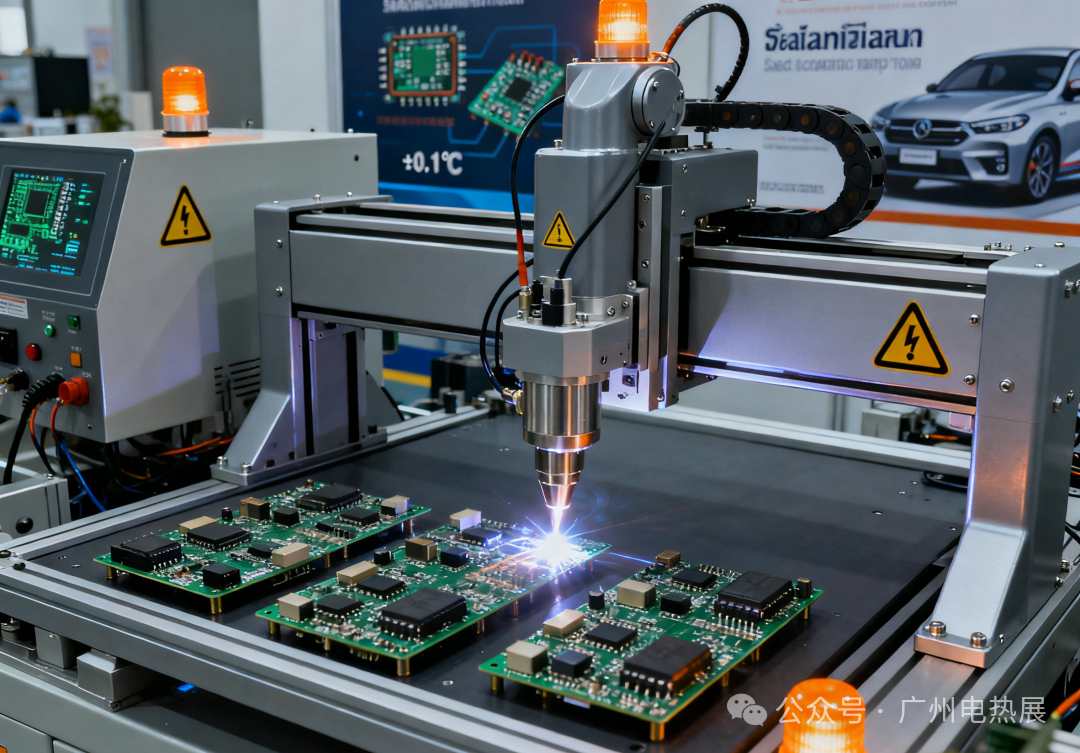

Industry 4.0's pursuit of ultimate product quality and process stability demands near-perfect temperature control across advanced manufacturing processes. In semiconductor packaging, high-end electronic component soldering, specialty material heat treatment, and precision injection molding, electric heating technology delivers highly stable and uniformly distributed thermal sources that ensure production reliability and product consistency.

With millisecond-level response speed and temperature control precision within ±0.1°C—capabilities unattainable through conventional heating methods—this technology establishes a solid "thermal foundation" for Southeast Asia's growing high-value industries such as electronics and automotive manufacturing.

02

The "Networked Node" of Smart Factories

Modern electric heating systems—including intelligent electric boilers, electromagnetic heaters, and industrial heat pumps—have evolved beyond standalone devices. By integrating sensors, embedded systems, and communication modules, they now function as critical nodes within the Industrial Internet of Things (IIoT).

Real-time data—such as energy consumption, operational status, and thermal profiles—can be collected and transmitted to cloud platforms or central factory management systems. This capability enables predictive maintenance, allowing the system to issue alerts before failures occur, while also supporting intelligent energy management aligned with production schedules.

Such advancements significantly enhance energy utilization efficiency, reduce operational costs, and fully align with the data-driven decision-making requirements of smart factories.

03

The "Clean Power" for Green Transformation

Amid mounting global pressure for emission reduction, the manufacturing sector in Southeast Asia faces an urgent need for green transformation. Unlike combustion-based heating methods reliant on coal or natural gas, electric heating technology achieves zero carbon emissions and eliminates pollutant release at the point of use.

As Southeast Asian nations continue to increase the share of renewable energy in their power grids, the inherent "green attribute" of electric heating will become even more prominent. This technology directly supports enterprises in meeting environmental targets and represents a critical pathway toward achieving sustainable manufacturing.

From establishing the foundations of precision manufacturing, to integrating into intelligent networks, and advancing the green transition, electric heating technology is being comprehensively embedded into the fabric of Southeast Asia's Industry 4.0—emerging as a core engine driving its journey toward efficiency, intelligence, and sustainable development.

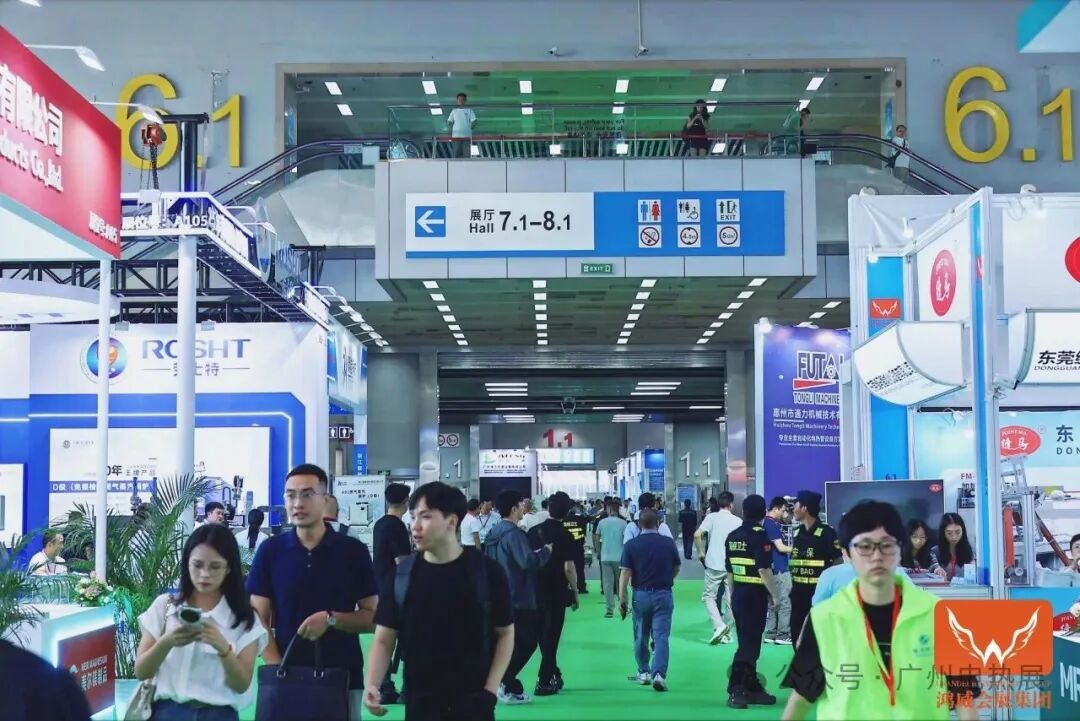

In March 2026, the Hongwei World Electric Heating Expo in Bangkok, Thailand, will bring together cutting-edge global technologies and solutions. Join us as we explore how to better unleash this “core thermal power” to empower your business for the future.

World Electric Heating Industry Exhibition