The World ElectricHeating Industry Expo will be grandly held at the China Import and Export Fair Complex in Guangzhou from September 16th to 18th.With the theme of "Green Power · Heating Up the Future", this exhibition focuses on the green, intelligent and international development trends of the electric heating industry. It covers an exhibition area of 25,000 square meters and is expected to gather more than 600 high-quality exhibitors from over 30 countries and regions. These exhibitors will collectively display more than 1,200 cutting-edge products, attracting over 35,000 professional visitors from home and abroad.

BEIJING SHOUGANG JITAIAN NEW MATERIALS CO., LTD is a subsidiary of Shougang Group Co., Ltd. Its predecessor, Beijing Steel Wire Factory, was established in 1956. In cooperation with Beijing University of Science and Technology (formerly Beijing Iron and Steel Institute), it developed electric heating alloy products, filling the domestic gap and making important contributions to the industrial development of New China. The company is committed to the R&D and production of high-end electric heating alloy materials, and has been deeply engaged in the electric heating alloy field for nearly 70 years.

JITAIAN has always adhered to the business philosophy of "Employees First, Customers Supreme, Quality Priority, and Glorifying the Country". It adheres to the dual-drive of technological innovation and management innovation, and focuses on the R&D and production of high-end electric heating alloy materials. Among them, multiple new materials such as HRE have successfully replaced imports, making JITAIAN the exclusive domestic supplier of electric heating materials in high-end equipment manufacturing fields including photovoltaic cells, chip manufacturing, ceramic sintering, exhaust gas treatment, and glass kilns.

01

Product Display

The company's leading products are high-end electric heating alloy materials. It has developed a batch of core technologies with independent intellectual property rights, which have reached the international advanced level and filled the shortcomings of the industry. It has achieved the R&D of high-performance Fe-Cr-Al alloys that can meet the service requirements above 1400℃, clean wire drawing technology, and high-end Fe-Cr-Al metal wires for the first time. These technologies have reached the international advanced level and filled the domestic gap.

In 2021, the high-performance Fe-Cr-Al alloy independently developed by the company and its production technology were evaluated by experts from the Beijing Metals Association as reaching the international advanced level. This scientific and technological achievement is mainly used in photovoltaic power generation, energy storage, urban clean heating, etc. It is more in line with the national "carbon peaking and carbon neutrality" policy direction, can effectively promote energy conservation and carbon reduction, and solve problems such as "chokepoints" (supply constraints), high prices, and delayed delivery of similar imported electric heating materials. At the same time, the company has obtained independent intellectual property rights for this achievement.

In 2022, the company achieved major breakthroughs in the R&D and achievement transformation of new clean wire drawing technologies. The new fine wire drawing technology that uses "water" instead of "oil" has significantly reduced the generation of hazardous waste oil sludge and lowered production costs; the R&D of the new "zero" dust wire drawing technology for thick wires has made breakthrough progress, eliminating dust pollution at the source, fundamentally solving the problem of cold drawing cracks in high-performance thick wires, and improving the consistency of product performance.

In 2023, the R&D and application project of high-end Fe-Cr-Al alloy wires ("Silk Steel") independently developed by Jitaian Company was evaluated by experts from the Beijing Metals Institute. This achievement has reached the international advanced level, broken the monopoly of imported Fe-Cr-Al alloy fiber materials in the domestic market, filled the gap in domestic high-end Fe-Cr-Al alloy fiber wire products, and enhanced the localization level of China's high-temperature gas purification, diesel vehicle exhaust treatment, and high-efficiency gas burner industries, contributing to the country's early realization of the "dual carbon" goals of "carbon peaking" and "carbon neutrality".

02

Honors and Qualifications

The company holds titles including "National-level Specialized, Refined, Characteristic, and Innovative Little Giant Enterprise", "National Green Factory", "National High-Tech Enterprise", "Zhongguancun High-Tech Enterprise", "Beijing Intellectual Property Demonstration Unit", "Beijing Enterprise Technology Center Certificate", "Changping District Industry-University-Research Integration Demonstration Enterprise", and "Beijing Specialized, Refined, Characteristic, and Innovative Small and Medium-sized Enterprise".

The company has led or participated in the formulation of 6 national standards, including GB/T 36516-2018 Fe-Cr-Al Alloy Fiber Wires for Motor Vehicle Purification Filters, GB/T 1234-2012 High-Resistance Electric Heating Alloys, GB/T 31942-2015 Fe-Cr-Al Alloy Foils for Metal Honeycomb Carriers, GB/T 37797-1991 Rapid Life Test Method for High-Resistance Electric Heating Alloys, GB/T 37797-2019 Precision Alloy Designations, and GB/T 40064-2024 Guidelines for Evaluation of Energy-Saving Technologies.

The company owns 68 intellectual property rights, including 31 core invention patents, 37 utility model patents, 7 software copyrights, and 11 independent trademark brands. All technologies related to these intellectual property rights have been transformed into high-tech products, contributing to the increase in the company's product market share.

The total value of existing R&D equipment and instruments exceeds RMB 10 million. The Electric Heating Research Institute has been recognized as a Beijing Municipal Enterprise Technology Center, and takes a leading position in electroslag metallurgy in China. It emphasizes cooperation with scientific research institutions such as universities, and has successively established industry-university-research cooperation relationships with the University of Science and Technology Beijing, Liaoning University of Science and Technology, etc. Multiple research topics have been identified, including improving molten steel purity and promoting green metallurgy, which have enhanced Jitaian's manufacturing capabilities.

The company vigorously researches and develops high-end electric heating alloy products. By advancing powder metallurgy technology, it has developed ODS-FeCrAl materials and achieved breakthroughs in key technologies. This has enabled the company to form independent production capabilities for high-end products, complete the localized replacement of key "chokepoint" products, and lead the development of the domestic electric heating alloy market.

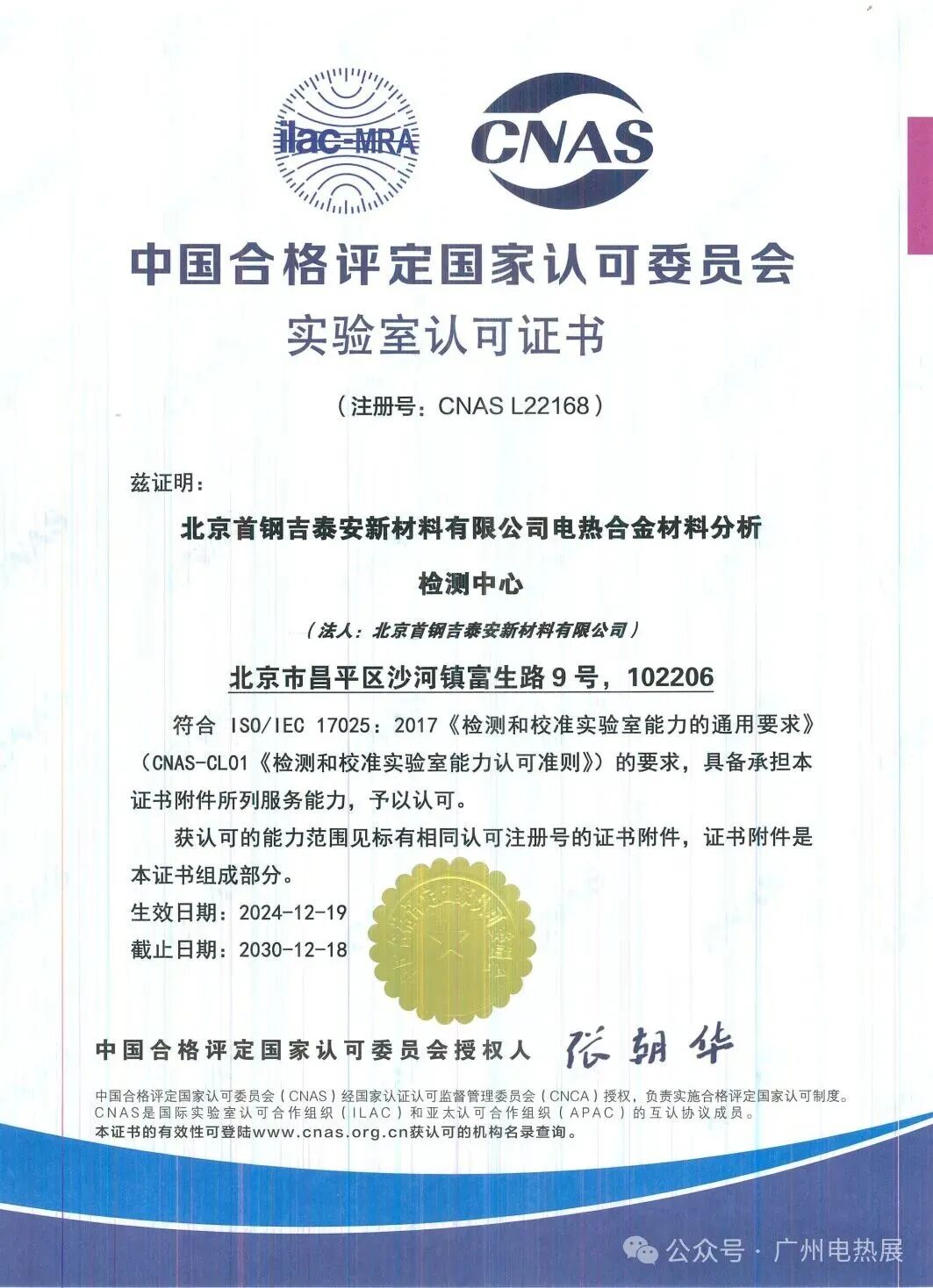

In 2024, the company successfully passed the accreditation of the China National Accreditation Service for Conformity Assessment (CNAS). This marks that the company's product quality has been recognized by national authoritative institutions, its testing service technical capabilities meet internationally recognized standards, and its market competitiveness has reached a new level.

We sincerely invite professionals engaged in high-end equipment manufacturing globally, including those in photovoltaic cells, chip manufacturing, ceramic sintering, exhaust gas treatment, and glass kilns, to visit the exhibition site and jointly discuss the future application of electric heating technology and industrial upgrading!